MODULES MENU

STEEL STRUCTURES

Steel is used for almost every type of structure, including industrial buildings, infrastructure, bridges, high-rise buildings, towers, etc. AXISVM provides a complete solution for the analysis and design of steel and other metal structures, including strength and stability verifications, fire design of members, and design of welded and bolted connections. Critical load multipliers and buckling shapes can be obtained from a buckling analysis for frame, truss, and shell structures. AXISVM also supports finding the optimal design solutions.

Detailed design report sample for a pedestrian bridge (compressed chord buckling) >>

- SD1 MODULE

- SD8 MODULE

- SD9 MODULE

The SD1 module performs the design and verification of steel structural members in ultimate (ULS) and serviceability (SLS) limit states. Flexural buckling, lateral torsional buckling, web shear buckling, and strength verifications considering axial forces, bending moments, shear forces, and their interactions are included. Both elastic and plastic design methods are allowed, depending on the cross-section classification. The class of the cross-section, buckling length (FB), and critical bending moment (LTB) can be determined automatically or can be specified by the user. The software verifies the deflections of beams and the sway of columns in SLS load combinations. Detailed documentation of the design calculations can be created.

Documentation sample (Steel member design) >>

Requirements / recommendations

- no requirement

DESIGN CODES

Eurocode 3

EN 1993-1-1

Swiss standard

SIA 263

Italian standard

NTC

CHARACTERISTICS

- automatic classification of the cross-section considering the internal forces

- design of members with class 4 cross-section

- automatic determination of critical axial force and critical bending moment

- detailed documentation of the design calculations

CROSS-SECTIONS

- rolled I profiles

- welded I profiles

- hollow rectangular profiles

- circular profiles

- single symmetric I profiles

- T profiles

- solid rectangular and circular profiles

! limited support for custom/arbitrary profiles

DETAILS

FLEXURAL BUCKLING

The critical axial force / buckling length of the design members can be calculated automatically. The buckling length, based on the geometry and the distribution of internal forces in the model, is determined with the so-called AutoNcr method.

The buckling length of each design member is computed considering the stiffenning effect of the connecting members. This method is based on the rules recommended by the European Convention for Constructional Steelwork (ECCS TC8: Rules for Member Stability in EN 1993-1-1: Background documentation and design guidelines).

LATERAL TORSIONAL BUCKLING

The critical bending moment can be calculated by a formula or automatically by AXISVM. This method creates a finite element sub-model for each design member and with which it determines the Mcr for each load combination. Variable cross-sections and cantilevers can be considered as well.

This method handles variable cross-sections and cantilevers as well. The finite element sub-model of a beam contains at least 30 finite elements in which each node has four degrees of freedom that are essential for the lateral torsional buckling. This method builds the beam stiffness considering two components: the first one is linear, the second one has geometric nonlinearity.

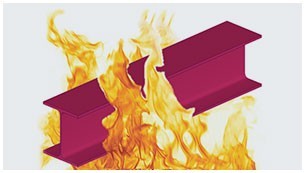

Fire design of steel members is available in the SD8 module. The design calculation considers the reduction in strength and stiffness of the steel material at elevated temperature that makes steel structures very sensitive to stability failure in fires. The design calculation can output the critical temperature, which is one of the essential parameters that determines the selection of intumescent coating thickness. The fire effect is given by a standardized prescriptive, parametric, or user-defined fire curve (considering simulation or fire test results). The steel temperature is calculated automatically by closed formula or by solving the two-dimensional heat conduction problem. The steel temperature calculation considers the effect of any passive fire protection material on the element.

Documentation sample (Steel member design for fire safety) >>

Requirements / recommendations

fire design of steel members is based on the steel member design, requiring the SD1 module to use the SD8 module

DESIGN CODES

Eurocode 1

EN 1991-1-2

Eurocode 3

EN 1993-1-1

EN 1993-1-2

Swiss standard

SIA 261

SIA 263

Italian standard

NTC

CHARACTERISTICS

- automatic calculation of steel temperature using a standard, parametric, or user-defined fire curve

- design of members with class 4 cross-section

- stability parameters for fire design

- calculation of critical temperature

- detailed documentation of the design calculations

DETAILS

TEMPERATURE DISTRIBUTION

The steel temperature is generally determined via closed formula from the design code. However, for I and rectangular hollow sections a more accurate temperature distribution may be used. Temperatures within the cross-section are calculated using a finite difference method to solve a two-dimensional heat conduction problem. The analysis considers the temperature-dependent thermal conductivity of the steel material.

CRITICAL TEMPERATURE

In many cases, the critical temperature (steel temperature where failure of the element occurs) must also be determined. For example, the thickness of the intumescent coating for fire protection is selected on the basis of section factor (A/V) and critical temperature. AXISVM determines the critical temperature along the design member, which can lead to a more economical and cost-effective design.

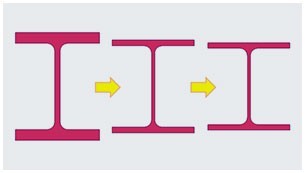

Cross-section optimization of steel structures makes previously defined and designed steel design members more efficient by fine-tuning the cross-section dimensions and reducing the self-weight. The optimization uses the steel design parameters previously assigned to the design members and can also be performed considering fire design rules for load combinations that contain a fire load case. The objective of optimization can be minimum weight, minimum height, or minimum width. AXISVM uses the Particle Swarm Optimization (PSO) method, a stochastic computational method for finding optimums.

Requirements / recommendations

- the SD9 module uses the steel design parameters previously assigned to the design members within the SD1 and SD8 modules, thus at least the SD1 module is a prerequisite to the use of the SD9 module

DESIGN CODES

The SD9 module is independent from standards.

CHARACTERISTICS

- the objective of optimization can be minimum weight, minimum height, or minimum width

- a heuristic search algorithm Particle Swarm Optimization (PSO) is invoked to find the optimum

- optimization with the consideration of fire design rules

CROSS-SECTIONS

- I profiles

- single symmetric I profiles

- rectangular and circular hollow profiles

- T profile

- C profile

- 2U profiles

! Variable cross-sections cannot be optimized

DETAILS

OPTIMIZATION ALGORITHM

Particle Swarm Optimization (PSO) is an evolutionary algorithm developed in the 1990s. The PSO process runs for a given number of iterations and, due to its stochastic nature, can find multiple local optimums. The number of iterations is determined by the program balancing running time with the fullest possible mapping of the search-space. If the algorithm finds no changes in the result after a sufficiently long period, it assumes there is a global optimum.

In multi-threaded mode, the search space is partitioned among the threads.

Design of steel members

- SD1 MODULE

The SD1 module performs the design and verification of steel structural members in ultimate (ULS) and serviceability (SLS) limit states. Flexural buckling, lateral torsional buckling, web shear buckling, and strength verifications considering axial forces, bending moments, shear forces, and their interactions are included. Both elastic and plastic design methods are allowed, depending on the cross-section classification. The class of the cross-section, buckling length (FB), and critical bending moment (LTB) can be determined automatically or can be specified by the user. The software verifies the deflections of beams and the sway of columns in SLS load combinations. Detailed documentation of the design calculations can be created.

Documentation sample (Steel member design) >>

Requirements / recommendations

- no requirement

DESIGN CODES

Eurocode 3

EN 1993-1-1

Swiss standard

SIA 263

Italian standard

NTC

CHARACTERISTICS

- automatic classification of the cross-section considering the internal forces

- design of members with class 4 cross-section

- automatic determination of critical axial force and critical bending moment

- detailed documentation of the design calculations

CROSS-SECTIONS

- rolled I profiles

- welded I profiles

- hollow rectangular profiles

- circular profiles

- single symmetric I profiles

- T profiles

- solid rectangular and circular profiles

! limited support for custom/arbitrary profiles

DETAILS

FLEXURAL BUCKLING

The critical axial force / buckling length of the design members can be calculated automatically. The buckling length, based on the geometry and the distribution of internal forces in the model, is determined with the so-called AutoNcr method.

The buckling length of each design member is computed considering the stiffenning effect of the connecting members. This method is based on the rules recommended by the European Convention for Constructional Steelwork (ECCS TC8: Rules for Member Stability in EN 1993-1-1: Background documentation and design guidelines).

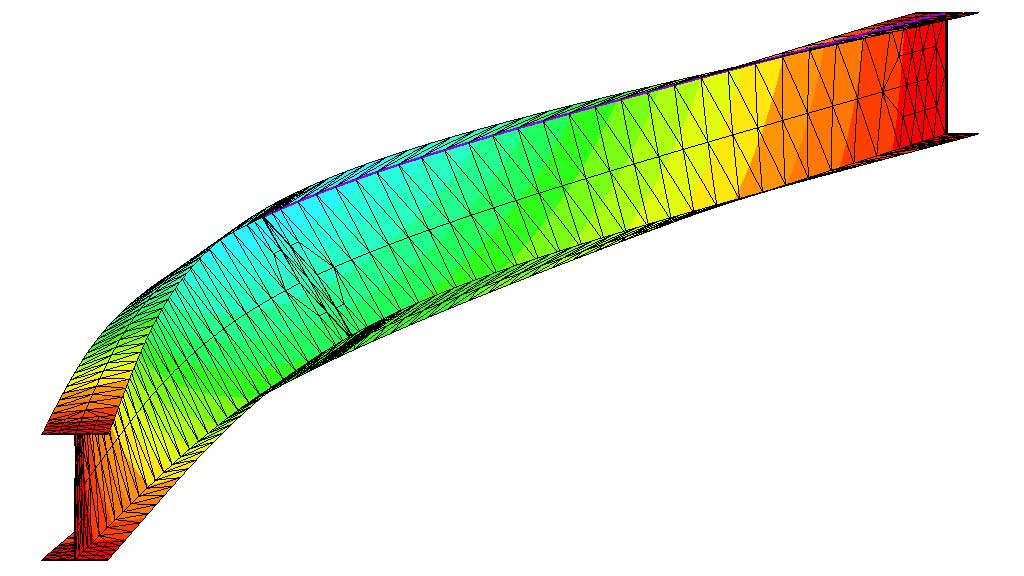

LATERAL TORSIONAL BUCKLING

The critical bending moment can be calculated by a formula or automatically by AXISVM. This method creates a finite element sub-model for each design member and with which it determines the Mcr for each load combination. Variable cross-sections and cantilevers can be considered as well.

This method handles variable cross-sections and cantilevers as well. The finite element sub-model of a beam contains at least 30 finite elements in which each node has four degrees of freedom that are essential for the lateral torsional buckling. This method builds the beam stiffness considering two components: the first one is linear, the second one has geometric nonlinearity.

Fire design of steel members

- SD8 MODUL

Fire design of steel members is available in the SD8 module. The design calculation considers the reduction in strength and stiffness of the steel material at elevated temperature that makes steel structures very sensitive to stability failure in fires. The design calculation can output the critical temperature, which is one of the essential parameters that determines the selection of intumescent coating thickness. The fire effect is given by a standardized prescriptive, parametric, or user-defined fire curve (considering simulation or fire test results). The steel temperature is calculated automatically by closed formula or by solving the two-dimensional heat conduction problem. The steel temperature calculation considers the effect of any passive fire protection material on the element.

Documentation sample (Steel member design for fire safety) >>

Requirements / recommendations

fire design of steel members is based on the steel member design, requiring the SD1 module to use the SD8 module

DESIGN CODES

Eurocode 1

EN 1991-1-2

Eurocode 3

EN 1993-1-1

EN 1993-1-2

Swiss standard

SIA 261

SIA 263

Italian standard

NTC

CHARACTERISTICS

- automatic calculation of steel temperature using a standard, parametric, or user-defined fire curve

- design of members with class 4 cross-section

- stability parameters for fire design

- calculation of critical temperature

- detailed documentation of the design calculations

DETAILS

TEMPERATURE DISTRIBUTION

The steel temperature is generally determined via closed formula from the design code. However, for I and rectangular hollow sections a more accurate temperature distribution may be used. Temperatures within the cross-section are calculated using a finite difference method to solve a two-dimensional heat conduction problem. The analysis considers the temperature-dependent thermal conductivity of the steel material.

CRITICAL TEMPERATURE

In many cases, the critical temperature (steel temperature where failure of the element occurs) must also be determined. For example, the thickness of the intumescent coating for fire protection is selected on the basis of section factor (A/V) and critical temperature. AXISVM determines the critical temperature along the design member, which can lead to a more economical and cost-effective design.

- SD9 MODULE

Cross-section optimization of steel structures makes previously defined and designed steel design members more efficient by fine-tuning the cross-section dimensions and reducing the self-weight. The optimization uses the steel design parameters previously assigned to the design members and can also be performed considering fire design rules for load combinations that contain a fire load case. The objective of optimization can be minimum weight, minimum height, or minimum width. AXISVM uses the Particle Swarm Optimization (PSO) method, a stochastic computational method for finding optimums.

Requirements / recommendations

- the SD9 module uses the steel design parameters previously assigned to the design members within the SD1 and SD8 modules, thus at least the SD1 module is a prerequisite to the use of the SD9 module

DESIGN CODES

The SD9 module is independent from standards.

CHARACTERISTICS

- the objective of optimization can be minimum weight, minimum height, or minimum width

- a heuristic search algorithm Particle Swarm Optimization (PSO) is invoked to find the optimum

- optimization with the consideration of fire design rules

CROSS-SECTIONS

- I profiles

- single symmetric I profiles

- rectangular and circular hollow profiles

- T profile

- C profile

- 2U profiles

! Variable cross-sections cannot be optimized

DETAILS

OPTIMIZATION ALGORITHM

Particle Swarm Optimization (PSO) is an evolutionary algorithm developed in the 1990s. The PSO process runs for a given number of iterations and, due to its stochastic nature, can find multiple local optimums. The number of iterations is determined by the program balancing running time with the fullest possible mapping of the search-space. If the algorithm finds no changes in the result after a sufficiently long period, it assumes there is a global optimum.

In multi-threaded mode, the search space is partitioned among the threads.

- SC1 MODULE

- 7DOF MODULE

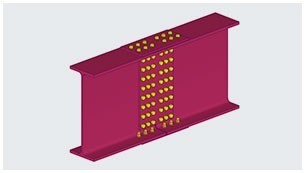

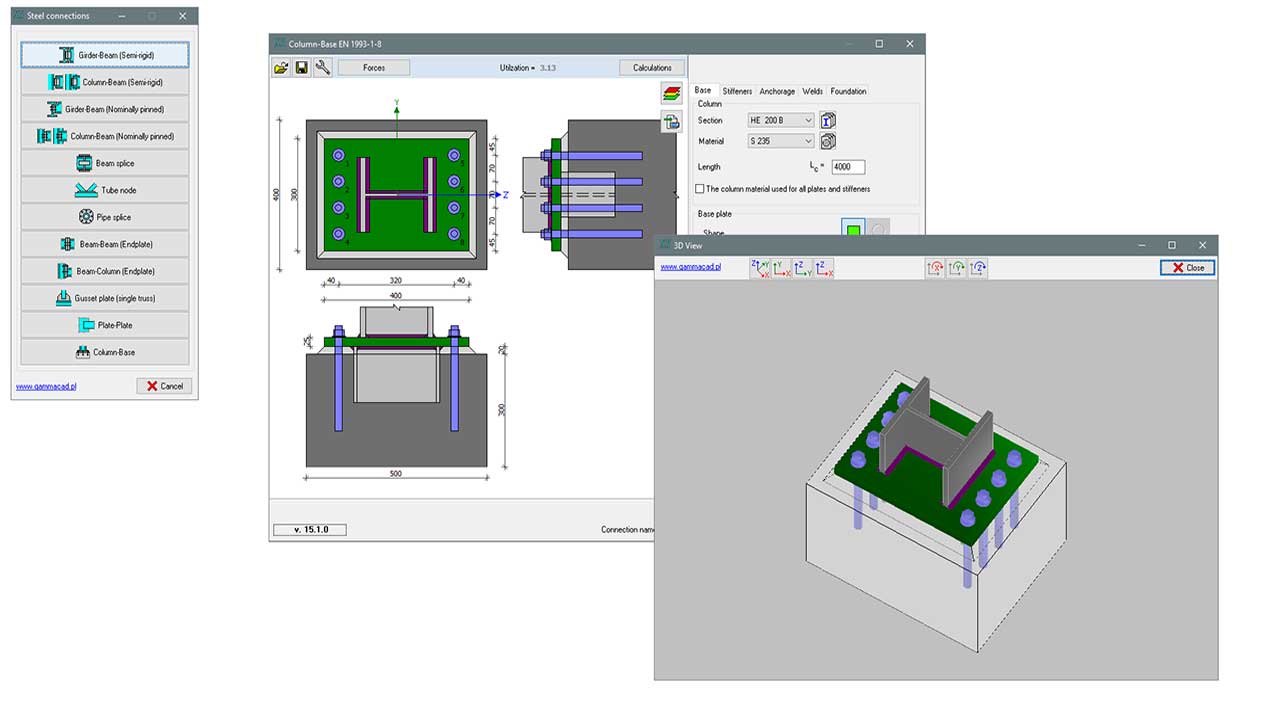

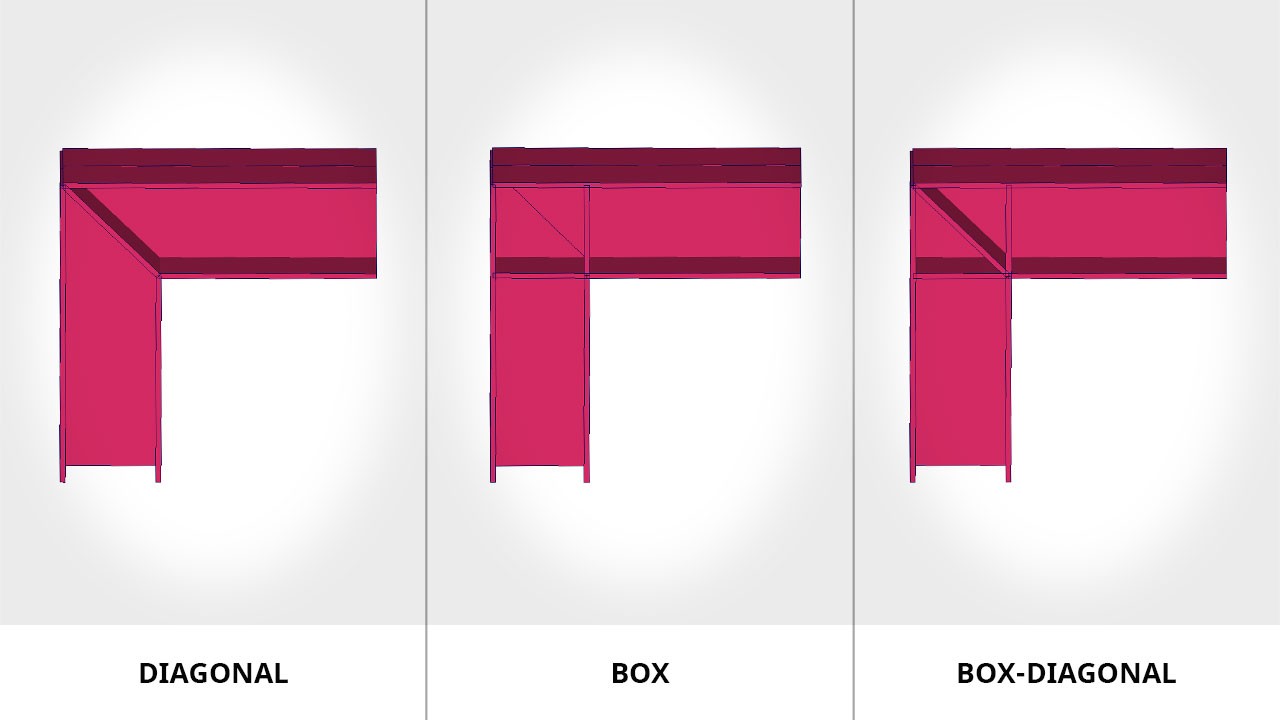

Design and verification of welded and bolted steel connections can be performed with the SC1 module. Altogether, thirteen connection types are supported. The so-called component method is applied that means that the resistance of the connection is determined on the basis of the resistances of its basic components. 3D rendered view and detailed documentation with view and section drawings can be generated. Documentation sample (Beam – column front plate joint ) >>

Learn more: SC1 API User’s Manual >>

Requirements / recommendations

- no requirement

DESIGN CODES

Eurocode 3

EN 1993-1-1

EN 1993-1-8

CHARACTERISTICS

- flexible and user-friendly definition of design parameters

- 3D view of the connection

- design of welded and bolted connections

- detailed documentation of design calculations

CONNECTION TYPES

- column – beam (semi-rigid)

- column – beam (nominally pinned)

- girder – beam (semi-rigid)

- girder – Beam (nominally pinned)

- beam – beam (end-plate)

- beam – column (end-plate)

- beam splice

- column base

- pipe splice

- gusset plate (single truss)

- tube node

- grider-beam rigid connection

- knee welded connection

DETAILS

STANDALONE STEEL CONNECTION

DETAILED DESIGN CALCULATION

Detailed documentation of the design calculations can be generated and attached to the report with one simple click. The documentation includes: 1) view and section drawings of the connection and dimension lines; 2) geometric and material properties of the components; 3) internal forces and moments at the node; 4) design results. The utilization results are colour-mapped. Green colour means it passed, and the red means it did not pass.

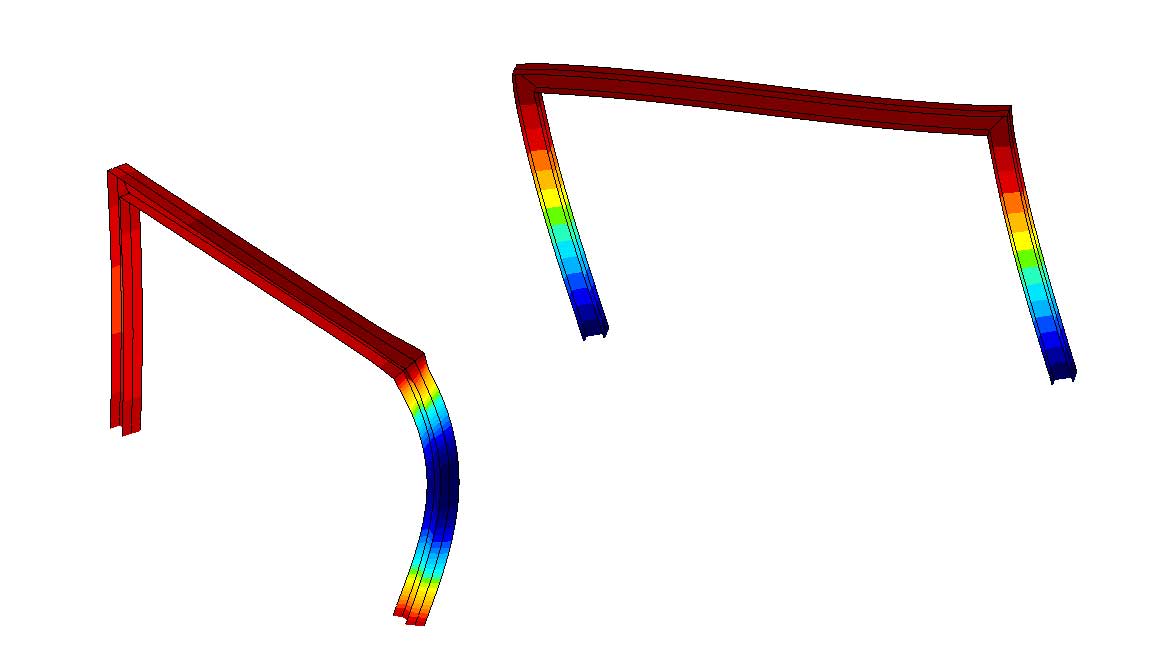

This module provides the option to define beams with 7 degrees of freedom. The additional, 7th DOF represents the warping of the cross-section.

A circular cross-section of a bar, or a circular hollow section will remain in-plane as a result of uniform twisting, however, all other section types will experience warping of the cross-section.

Warping occurs when the twisting of a member results in the cross-sections distorting out-of-plane along the direction of the members longitudinal axis. If the out-of-plane distortion is restrained or prevented, longitudinal stresses and strains develop in the member. Warping can be constrained by a support or concentrated torque.

Constrained warping can significantly affect the stress distribution in thin-walled beams and columns, which should be considered in the design. Warping is also important if the members of the structure are sensitive to lateral-torsional buckling.

Requirements / recommendations

- 7DOF is an add-on module to the basic packages (analysis options), and is recommended when designing beam structures with a tendency to warp

DESIGN CODES

The 7DOF module is design code independent

CHARACTERISTICS

- an element type to be used for modeling thin-walled steel structures

- the so-called warping transmission is based on Basaglia et al. [1]. Since the 7th degree of freedom is assigned to the beam elements, the degree of freedom of different beam elements connected to a node is not always the same. The warping transmission depends on the structural design of the nodes, which can be specified in the program by a transmission multiplier

- in the case of a nonlinearly elastic or plastic material model, the software considers the additional stresses due to the inhibited warping

[1] C. Basaglia, D. Camotim, N Silvestre. Torsion warping transmission at thin-walled frame joints: Kinematics, modelling and structural response, Journal of Constructional Steel Research (69), 2012

DETAILS

- SC1 MODULE

Design and verification of welded and bolted steel connections can be performed with the SC1 module. Altogether, thirteen connection types are supported. The so-called component method is applied that means that the resistance of the connection is determined on the basis of the resistances of its basic components. 3D rendered view and detailed documentation with view and section drawings can be generated. Documentation sample (Beam – column front plate joint ) >>

Learn more: SC1 API User’s Manual >>

Requirements / recommendations

- no requirement

DESIGN CODES

Eurocode 3

EN 1993-1-1

EN 1993-1-8

CHARACTERISTICS

- flexible and user-friendly definition of design parameters

- 3D view of the connection

- design of welded and bolted connections

- detailed documentation of design calculations

CONNECTION TYPES

- column – beam (semi-rigid)

- column – beam (nominally pinned)

- girder – beam (semi-rigid)

- girder – Beam (nominally pinned)

- beam – beam (end-plate)

- beam – column (end-plate)

- beam splice

- column base

- pipe splice

- gusset plate (single truss)

- tube node

- grider-beam rigid connection

- knee welded connection

DETAILS

STANDALONE STEEL CONNECTION

DETAILED DESIGN CALCULATION

Detailed documentation of the design calculations can be generated and attached to the report with one simple click. The documentation includes: 1) view and section drawings of the connection and dimension lines; 2) geometric and material properties of the components; 3) internal forces and moments at the node; 4) design results. The utilization results are colour-mapped. Green colour means it passed, and the red means it did not pass.

Beam elements with 7 degrees of freedom

- 7DOF MODULE

This module provides the option to define beams with 7 degrees of freedom. The additional, 7th DOF represents the warping of the cross-section.

A circular cross-section of a bar, or a circular hollow section will remain in-plane as a result of uniform twisting, however, all other section types will experience warping of the cross-section.

Warping occurs when the twisting of a member results in the cross-sections distorting out-of-plane along the direction of the members longitudinal axis. If the out-of-plane distortion is restrained or prevented, longitudinal stresses and strains develop in the member. Warping can be constrained by a support or concentrated torque.

Constrained warping can significantly affect the stress distribution in thin-walled beams and columns, which should be considered in the design. Warping is also important if the members of the structure are sensitive to lateral-torsional buckling.

Requirements / recommendations

- 7DOF is an add-on module to the basic packages (analysis options), and is recommended when designing beam structures with a tendency to warp

DESIGN CODES

The 7DOF module is design code independent

CHARACTERISTICS

- an element type to be used for modeling thin-walled steel structures

- the so-called warping transmission is based on Basaglia et al. [1]. Since the 7th degree of freedom is assigned to the beam elements, the degree of freedom of different beam elements connected to a node is not always the same. The warping transmission depends on the structural design of the nodes, which can be specified in the program by a transmission multiplier

- in the case of a nonlinearly elastic or plastic material model, the software considers the additional stresses due to the inhibited warping

[1] C. Basaglia, D. Camotim, N Silvestre. Torsion warping transmission at thin-walled frame joints: Kinematics, modelling and structural response, Journal of Constructional Steel Research (69), 2012